Relevance of Enterprise Resource Planning( ERP)-

As per expert, Supply Chain Management supports –

(1) Material

flow

(2) Information

flow

(3) Financial

flow

These flows are

bolstered by three pillars processes,

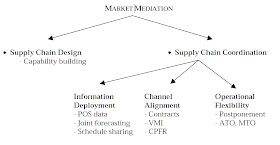

organizational structures and enabling technologies.Supply Chain Management is not only about specifying

customer zone, manufacturer and distribution selection, allocation of products,

but also about the prioritization of

capabilities to be developed. With this

effective supply chain strategies

depends on exemplary coordination which can be divided in further 3 parts –

(a) Information

deployment – Point-of-sale(POS) data, Joint forecasting , Schedule sharing

(b) Channel

alignment – Contracts , Vendor-managed inventories (VMI), Collaborative

planning forecasting and replenishment (CPFR)

(c) Operational

flexibility – postponement , Assemble-to-order (ATO) , Make-to-order (MTO)

Emergence of IT and SCM transformation collided and created

a requirement for solution which can be critical enabler of superior supply

chain. Enterprise resource planning (ERP) can be seen as combination of

business processes and information technology. ERP converts functional

orientated organization into a process oriented one. Hence require change

management , cross functional initiatives and may lead to complex structures. ERP

is an umbrella term for integrated business software that controls information

structure, controlling a broad range of activities from supplier on floor to

accounting. ERP can provide for

following functionality:

Transaction processing

engine: integrates management of data

throughout the enterprise

Work flow management :

controls numerous process flows that exist in enterprise

Decision support: assists in

creation of plans or deciding in creation of specific customer orders

Limitation of current ERP -

(2) Lack

of flexibility in adapting to

ever-changing supply chain needs

(3) Lack

of more advanced supporting functionality beyond transaction management

(4) Lack

of open, modular, Internet-like system architecture

(5) Information

exchange

Need of the hour –

ERP is going the problem of “ too much information”( TMI)and

“too much software” (TMS). The jumble of ERP, CRM , Supply Chain and BI is

spread all over the globe. A research suggest that CIO and exec accept that

only 64% of enterprise system’s core functions are utilized. Due to company

growth, business line change , new facility, consolidation operations, acquisition

a lot of changes and upgrades are needed in ERP which makes it hard implement

and be successful.

Improving current ERP -

ERP does not have a one-size-fits-all approach. It requires

a lot of customization or requires organization to change the business

processes. Different ERP products offers different degree of specialization

towards different verticals. Another emerging trend is SaaS (Software-as-a-Service) or web-based

software, which can change the integration and implementation trend. The

adoption is still evolving and varies between enterprise application markets

and applicability. But this approach is viable option for small/mid-market

enterprise and it also provide modular way to expand existing business. This 4th

generation computing model represents both an opportunity and challenge. The opportunity is to optimize computing infrastructure,

enterprises while evaluating the challenges/perceptions around the security of

data on the cloud.

Another trend is social

computing, which is helpful in analyzing customer’s proactive and reactive behavior for a firm or product. Social computing technologies provide easy way to provide consumer feedback.

Till this point, social media is limited to business-to-customer(B2C) but

leaders are leveraging social networks for better collaboration with customers,

suppliers and outsourced manufacturers and

other partners. This initiative

can also provide platform to improve internal communication and

collaboration between co-workers and across functional groups and departments.

Mobile device

integration can be utilized in the wake of outstanding network, storage

capacity and broadband speed of new handheld devices. The usage of mobile

devices can result in improved data

accuracy and increased mobility and convenience, thereby streamlining

movement and reducing human errors. This will also improve data validation and

reduce latency while dealing with orders.

These factors can bring huge saving, benefits and usability factors. They are significant reasons to revolutionize the ERP with its relevance to supply chain.

Reference -

Great post. You know we all think about this very topic. Eresource provides manufacturing solutions to midsize Manufacturing Companies with unformed, integrated, on-demand ERP solution generate new revenue streams. erp for manufacturing helps you also cut down production bottlenecks.

ReplyDeleteThanks for sharing such a nice post...

I like the way you start and then conclude your thoughts. Thanks for this nice information.

ReplyDeleteOrder Management Software System