“Every

morning in Africa, a gazelle wakes up, it knows it must outrun the fastest lion

or it will be killed. Every morning in Africa, a lion wakes up. It knows it

must run faster than the slowest gazelle, or it will starve. It doesn't matter

whether you're the lion or a gazelle-when the sun comes up, you'd better be

running.”

-Abe

Gubegna

I

first heard this story as an African fable when I was probably entering high

school. It impacted me a lot thinking

about how we are constantly on the run, trying to get ahead in the race. The

race has pushed us to discover new limits we can achieve, both physical and

intellectual. Intense competition across industries, products and services has

forced decision makers to think and rethink and rethink again on ways they can

better their product and convert that effort to measurable dollars.

It is because of

this intense race that process improvement techniques such as Six Sigma and

Lean have taken center stage. They focus on Kaizen, or continuous improvement,

which they hope will directly impact their overall productivity and eventually

profits. Toyota Production System, or TPS, which was developed by Toyota in the

post World War II era introduced the concepts in process improvement, which we

today know as Lean practices.

Flexibility!

That is the key ingredient of Lean processes. Can my process produce the right

amount of product at the demand levels given at that time? If tomorrow, my

competitor goes out of business and the demand level of my products goes up

drastically, my process should be able to be meet the demand with by minimizing

non-value adding activities. Lean practices have been developed around the idea

of minimizing these unnecessary tasks. In 1961, General Motors introduced the

concept of using industrial robots to compliment the Lean way of thinking in

the automobile industry with the “Unimate” robot. This provided a major leap

in further improving process efficiency by reducing long-term costs and

providing immense flexibility to the processes driving it to be more lean.

The decision to

either use or not to use an industrial robot is a big hurdle that the company

has to assess. If the company is looking for short-term profits, it is really

not a good idea. But, like GM and Toyota got it right early on, if you are

aiming to survive long and strong in the industry and short-term losses are

sustainable, industrial robots are the right way to go. So how can we integrate

robots into the lean manufacturing process?

The principle of

Lean processes as discussed before is to reduce the non-value adding activity.

If a customer is not going to get the benefit, don’t do it! For example

consider the auto shop where the toolbox of frequently required tools is

located about 20 yards from the location the worker is situated. The worker

wastes time in going to and from the toolbox every time he needs one. That is

40 yards of wastage, which could be translated into time wastage and eventually

lowered productivity. By using robots, this waste is automatically eliminated.

Despite the obvious advantages that automation provides, critics have

questioned benefits of integrating them into the lean manufacturing process.

So my company

installed the industrial robots and I am going to produce a lot and lot and lot

of product. They will run 24 hour a day and 7 days a week. Is this lean?

Absolutely not! Lean does not mean producing as much as I can, which obviously

the robots excel at. If I produce more than what I need to supply, that is a

waste which I do not desire. The flexibility of the robots is such that I can

ask them to produce what I want, how I want, how much of it I want and when I

want. That is the most efficient use of the robots that will lead to reduced

overhead costs associated with the process. But what does the future look like

if I keep on increasing the robot work force to continuously improve my

processes? How far can we stretch the limits with Kaizen?

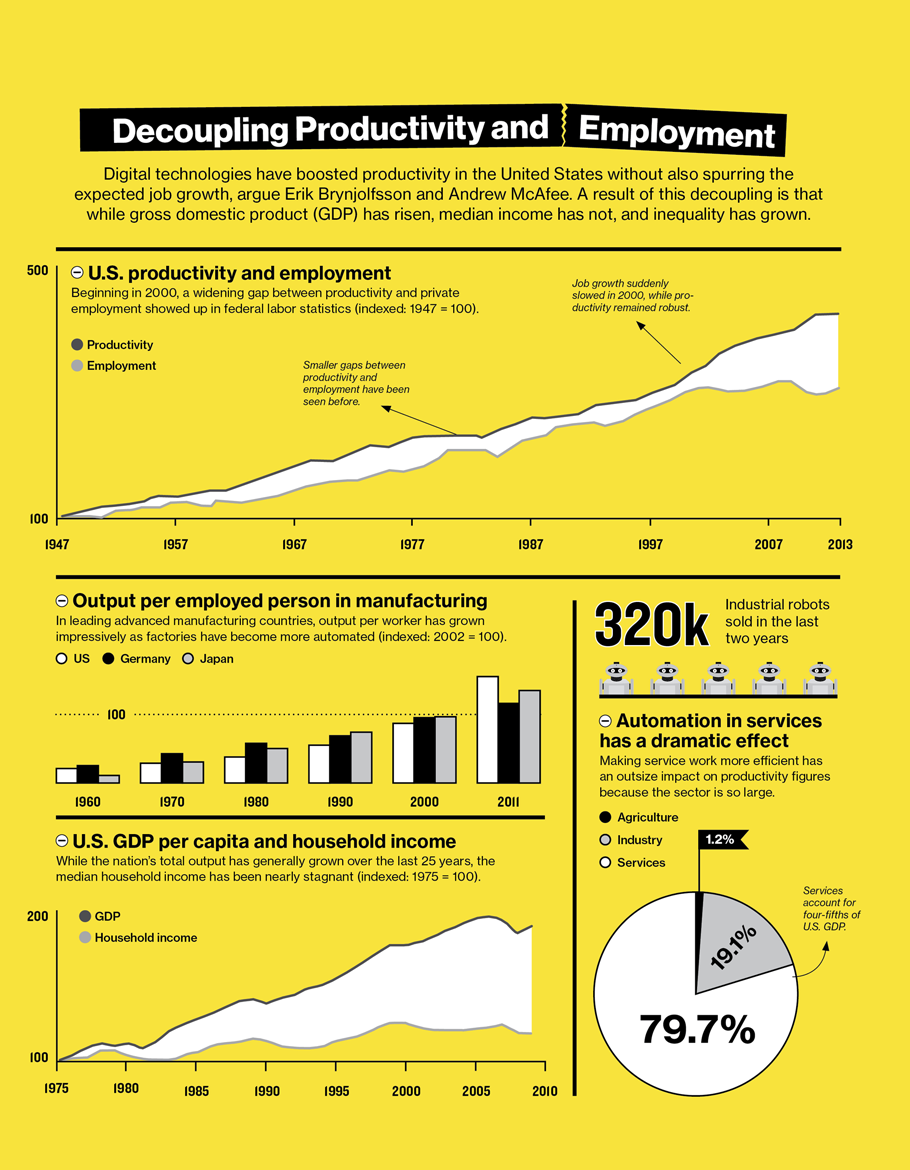

Professor. Erik Brynjolfsson

from the MIT Sloan School of Management has studied this fundamental workforce

shift from humans to robots and presented some very troubling facts that we

will face in the future. According to Brynjolfsson, automation and technologies

such as industrial robots are destroying human jobs with every passing day.

Process improvement strategies like lean and six sigma are becoming more

prominent with the lion and gazelle race going on. This only means that there

will be more companies introducing non-human technologies to improve their

processes and reduce the waste. But are we destroying our future jobs in this

“Kaizen” race? Are these “Blue collared robots” are all set to take over our blue collared jobs for a leaner and better future? I will leave you with that

thought to ponder over.

Exhibit 1: How technology is destroying jobs

Source: http://www.technologyreview.com/sites/default/files/images/destroying.jobs_.chart1x910_0.jpg

Sources:

http://www.technologyreview.com/featuredstory/513746/baxter-the-blue-collar-robot/

Decoding the DNA

of the Toyota Production System (HBR OnPoint Enhanced Edition), Steven J. Spear; H. Kent

Bowen

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.