New systems take time to train employees and learn how to use effectively. Many global markets are volatile and are subject to a number of continuously changing variables and complicate growth. In emerging markets, technology is not always available, nor is the manpower to effectively manage these systems (1).

A new thought process has emerged in supply chain management known as incremental change (2). The basis of the concept is making small changes over a period of time to stay ahead of competitors. The small changes allow for shifts in dynamic markets, and to continuously refine strategies that the company chooses to employ.

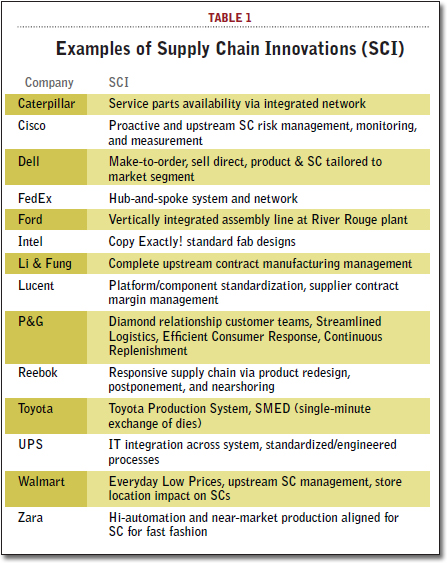

Some examples of recent (and not so recent) incremental changes:

The concept of incremental change could be a very important one to modern supply chain management methodologies. Incremental changes have the distinct advantage of being flexible in quickly changing markets. One of Amazon's incremental changes was to use regional hubs rather than warehouses that are farther apart to store inventory (3). Caribou Coffee was able to better keep up with changing customer demand by switching their analytic strategy from analyzing monthly to looking at statistics each week (4).

In the 21st century, there are many unknowns with market demand. Consumers have increasing diverse and changing tastes, and are becoming accustomed to a certain responsiveness from services they give business to. Competitors are increasing in number and are becoming more innovative and adapting to market demands, increasing the need to keep up with competition. There are more dynamic changes that a firm needs to respond to, and the need to keep a leg up on competing firms is ever more important with labor and technological shifts.

Incremental changes provide a means of keeping continual improvement. They are often available at a much lower cost that an extensive implementation, have low training or transfer costs, and can often be implemented immediately or within a short window. Small continuous changes allow a firm to keep up with changing technology/demand/operational shifts. It's also possible that one bad decision will not break a firm, and the company will be able to rebound easier from the mistake. As uncertainty in businesses change, incremental change in supply chains becomes a more and more viable option.

Questions for further thinking:

How do incremental changes differ between industries?

How can you define an incremental change versus a monumental change?

When does a firm need to upgrade technology?

How can a company effectively diagnose a mistake and reverse an incremental change?

References:

1) http://www.supplymanagement.com/news/2014/better-use-of-technology-will-help-emerging-market-supply-chains-says-accenture

2) http://www.supplychain247.com/article/how_many_supply_chain_innovations_are_truly_revolutionary

3) http://www.mwpvl.com/html/amazon_com.html

4) http://www.marketwatch.com/story/caribou-coffee-shares-its-journey-to-supply-chain-success-at-sop-innovation-summit-2014-09-23

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.