A collection of resources and commentary providing an introduction to supply chain management and related systems for students, practitioners, and anyone else interested in learning more about how to design, manufacture, transport, store, deliver, and manage products.

Wednesday, November 30, 2011

More about Energy-efficient Supply Chain

Reasons to rethink offshoring

Earlier this year, several of Apple's suppliers in China were accused of heavily polluting the environment by Chinese NGOs. See full report here, and related news link here. While rumor has it that the investigations, targeted at certain high-profile U.S. companies, were to retaliate the U.S. government's demand on the Chinese government to stop controlling RMB, the U.S. companies took the hit through dropping share prices.

No matter how hard Apple tries to keep its supply chain secretive, the impacts of such investigation were immediately felt even if many of the manufacturers examined were only suspected to be Apple's suppliers. Even if Apple cares about environmental pollution, with its suppliers in China and often managed by companies from yet another country, Apple's visibility through the supply chain for factors other than quality and cost is low. Apple had to go through 3rd party consulting to receive environmental information from its suppliers about its products since the suppliers refuse to let Apple understand the process and cost structure. Getting the information is difficult, let along helping the suppliers to become more environmentally sustainable.

If Apple's suppliers were in the U.S., the suppliers would be regulated consistently by EPA. Apple's risks is more likely to be limited if one of its suppliers were found to be violating the regulations. When companies are making decisions whether to offshore production, how feasible it is to control the environmental aspects of the production may now become a new factor to be considered.

Where's my pizza?!?!

Despite the relatively new commercial, Domino's actually unveiled the Pizza Tracker feature as part of their online ordering system in 2008. While you can argue the merits of or need for being able to track to progress of your pizza order, the parallels to distribution center tracking are clear. Specifically, rather than placing some sort of RFID or similar tag on the physical pizza, Domino's employees hit buttons as the pizza moves through stages of the process (e.g. dough stretched, sauced, baking, out for delivery) process that allow for the Pizza Tracker system to update. It's a strikingly similar "updating" process to that in the Kiva warehouse video Professor Zak showed us where the employee hit the button to indicate an order had been filled or a new order was ready to fill.

Even though there is something rather silly about remotely following the process of your pizza being made, Domino's seems to be taking the idea of integrating technology into their businesses very seriously. In 2009 and 2010 the company went on something of a hiring binge for software and hardware engineers and employees. I wasn't able to see if the new employees were able to update and revamp the Pizza Tracker system, but it is clear that they have helped Domino's move into the customer's mobile device with the creation of an iPhone app in 2011.

While tracking products is nothing new, the concept of the customer being able to track the product through the steps of its production process is rather striking. A more clever and perhaps less trivial application of the same idea is to allow for the customer to be able to track the progress of the cable guy, or any utility service person for that matter. TOA Technologies has designed a software service that does just that and might be able to help reduce the estimated $37.7 billion in waste from customers having to wait an average of 4.3 hours for "scheduled" repair and service calls.

So what do you think about the Pizza Tracker? Do you side with Domino's technology chief, Chris McGlothlin, who says, "It's an emotional roller coaster when you order. Customers wonder: Did they get my order? Are they taking care of me? Will it show up?" Or do you side with Brian Kardon, chief strategy officer at Forrester Research, who says, "It's technology in search of a problem. I don't know how many consumers are twisting and turning over the state of their delivery pizza."? If you agree with Kardon, do you think TOA Technologies program is a better "problem" for the technology? And what other possible applications can you think of for the technology?

Supply Chain Networks

As we all know, redesign and optimization of supply chain networks is a very hot topic these days and every other day, we read stories of companies trying to overhaul their transportation network for best possible profits and improving their ability to meet the customer demand. My first introduction to Supply Chain Networks came at the Decision Making under Uncertainty Class when we were taught to come up with Solver models to design a low cost network Strategy to solve transportation problems.

IBM ILOG Supply Chain Optimization, Oracle® Strategic Network Optimization are some of the famous examples of Supply Chain Network Optimization tools used by companies to design an efficient network. These software products, allow you to decide the most optimal network, taking into consideration the complex cost assumptions and other constraints that drive the business. These software run with such high Business Intelligence that it allows you to decide on answers for tough trade off questions such as inventory pre-build versus overtime, or single source vs. multi-source using what-if Scenarios and judge based on evaluation of currency fluctuations and impacts of mergers and acquisitions to your distribution and supply network. This was fascinating for me, however I was interested in knowing how accurate the results of these software can be, when the demand is not predictable. This led me to research on such cases and one interesting reading was on Northpole.com, a leader in the Toy Industry.

Northpole is considered to have one of the most efficient supply chains in the world. At Northpole, the supply chain effectiveness starts at the top, where the CEO, clearly understands the need for an effective supply chain for the company’s success. Northpole considers Customer Intimacy as one of its key value drivers and hence the supply chain strategy is essentially a five year roll out plan with annual updates to budgets. Northpole acquired a network planning Tool Company and has deployed a small group of staff to evaluate network improvements, on a constant basis and provide expert thoughts on the results that the software generates. This tool is used for determining sourcing strategies, identifying constant flow path optimization and to determine which products need to be made in-house.

Northpole has a highly seasonal but also at times has an unpredictable demand. The company is using techniques such as Predictive Demand planning and Sensing to aid its network team as the toy demand is highly unpredictable. They constantly monitor social networking sites for clues on demand and tweak their networks accordingly. This company essentially follows a pull-based strategy to draw down inventories of slow movers and tags with companies like overstock.com and other retail channels to get rid of the excess stock. The most interesting part of managing their network was that they use the Just-in-time technique for certain products like Board Games that use standard boards and boxes. These are printed at the last moment based on need of the product.

However, Northpole is not completely free of Supply Chain woes. Highly fuel costs and aging workforce are adding concerns to the network optimization team. It will be critical for Northpole to consider these factors in taking networking decisions. I would love to hear your thoughts on the idea of using such networking software with dedicated teams and what kind of unquantifiable/qualitative aspects, that need to be considered in complementing the results of the software, given a situation of variable/unpredictable demand and how it ultimately affects the final decisions of deciding an optimal network.

Reference: Supply Chain Digest- North Pole Supply Chain Case Study

Too Small to Fail

Tuesday, November 29, 2011

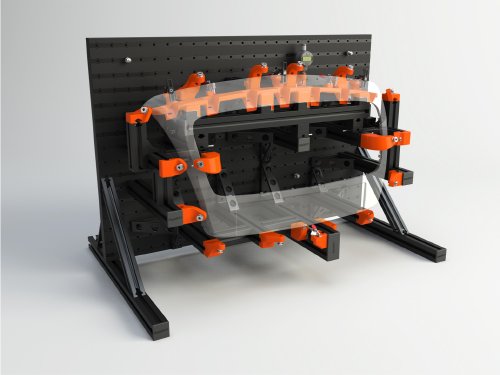

3-D Printing Revolutionizes Production Of Quality Assurance Materials In Auto Manufacturing

RapidFit+ (a product of Materialise) has used 3-D printing technology to transform the quality assurance process for manufacturers, enabling the production of previously difficult or even unthinkable designs and making the entire process cheaper, faster and more responsive to design changes.

I believe that this technology has been primarily used in the automotive industry, so far. In these supply chains, smaller manufacturers produce parts that are put into larger parts by other manufacturers, which may be added to even larger components by another manufacturer, and so on until the final components are installed by the automaker in a vehicle. These supply chains can be incredibly complex, and if one manufacturer anywhere on the chain produces parts outside of a very strict set of specifications the whole system quickly falls apart.

In the past, individually machined (and very expensive) aluminum or steel relief-molds were used by manufacturers to check the accuracy of parts being produced. When a part was produced, it could be slipped into the mold and checked for accuracy. Today, the introduction of new hyper-precise 3D printing technology and the ubiquity of the Internet mean that custom 3D printed objects can be used to verify parts as they move though the manufacturing process.

At RapidFit+, an original equipment manufacturer (OEM) can use an online platform to upload 3D and engineering data who then works out a precise rig that can accurately check the dimensions of the finished part within +/- 0.05 mm. At any time the OEM can use the online platform to approve the design or make changes to the parts if necessary. Once approved, a fixture is produced and the precision calibration units are 3-D printed (These are orange things you see in the photo at the top of this post.) and sent to the part manufacturer.

This technology brings numerous advantages to the supply chain. As previously stated, these quality assurance rigs were traditionally made from a solid block of metal. Aside from the huge expense of creating it, these rigs were only accurate for a single part, possibly on a single model of car. With the adoption of 3-D printing, adjustments can be made when small changes are ordered, or for similar parts between different models. Further, these new quality assurance rigs can be produced cheaply, quickly, durably (tests have shown that even after 10,000 cycles wear is limited to only a few microns) and as previously stated the OEM can send design changes in real time. And because the rigs are built on a modular structure, and only the precision "locators" are custom printed, a rig can be configured in multiple ways for multiple parts depending on needs of the part manufacturer.

Currently, RapidFit+ uses this technology in-house, but it is not impossible to see a future where individual part manufacturers invest in 3-D printing technology and their customers are able to upload design specifications directly.

Question: Within the field of supply chain management, for what other applications could 3-D printing technology be suitable?

RapidFit+ using 3D printing to check mass produced parts

Logistical Troubles for the US Military

The practical approach to productivity

A lean manufacturing initiative focuses on cost reduction and increases in turnover by systematically and continuously eliminating non-value-added activities. In today's competitive market, lean is turning out to be "the solution" to manufacturing industries across the spectrum for survival and success.

Lean manufacturing helps organizations to achieve targeted productivity and more by introduction of easy-to-apply and maintainable techniques and tools. Its focus on waste reduction and elimination enables it to be engrained into organization culture and turns every process into a profit center. Thousands of companies worldwide have achieved tremendous productivity and return on investments by implementing lean practices and techniques. India has witnessed many success stories in its automotive, process and other industries.

In a nutshell, lean manufacturing is all about driving toward achieving profitability and productivity through continuous improvement and resource waste elimination. It is an organizational culture as well as specific practices with clear goals.

In today’s competitive world, while large-scale companies have taken the first steps to implement lean in their organizations, small and medium establishments (SMEs) also need to follow the lean thinking and implement the same to achieve their set goals.

Role of 3rd party service providers in Logistics

As supply and distribution chains have become longer and complex businesses have begun to realize that increased transportation costs can reduce the benefits of manufacturing where labor is cheap. The congestion and bottlenecks of a transportation network adds to the woes and has a huge impact on businesses.

While reading the "The Threat of Global Gridlock" article a question that touched my mind was why not utilize the existing network of 3rd party logistics giants such as Fedex, UPS and aim at cutting down the underlying costs of transportation. These organizations already have an excellent air and road network that spans the entire globe. Businesses can leverage this network and improve their supply chain mechanism and cut down on inventory and overstock costs.

Companies like Fedex, DHL and UPS have an effective network infrastructure that can help businesses avoid some of the degenerating effects of transportation congestion and bottlenecks. Although, these companies are not into sea-based transportation , but their air/road network can be used to transport some critical components and help businesses to reach out early to customers.

Moreover, these companies have a very good presence through out the world. As manufacturers are trying to move to newer lands where the labor costs are not soaring, a tie-up with logistics giants like Fedex, UPS can help businesses in the distribution and transportation of goods without any extra overhead.Businesses need not worry in setting up a transportation channel while moving to newer lands, and can transfer the burden to logistics companies.

This presents a major strategic opportunity for businesses and can have a size-able impact on profitability and help them build a rapid-response supply chain.

Effect of Big Data on Supply Chain Management

Big data are large data sets whose data sizes are a constantly moving target ranging from a few dozen terabytes to many petabytes of data in a single data set. Examples include web logs; RFID; sensor networks; social networks; social data , Internet text and documents; Internet search indexing.

" The main focus on collecting the sales data (Big Data) is to analyze the customer behavior, the big data streaming from the supply chain operations can be leveraged for optimizing processes, automate decision making, and increasing overall efficiencies. Part of this big-data wave is being driven by the RFID tags that are slowly becoming embedded in all parts of supply chain and have moved from pallet-level tagging to item-level tagging and the other big part is the ability to capture, analyze and use the real-time POS data from the stores and other selling-channels. Together, these two data streams can be leveraged to better understand demand and manage inventory, supplies and resources."

Jack Daniels Distillery: A success story in Lean Manufacturing

Hola Amigos! I hope all of you enjoyed your mid semester break and had a wonderful Thanksgiving. Being new to America, I decided to embark on a road trip with my friends to explore the fine American culture. One of the last things that I expected to learn on this trip was 'Lean Manufacturing'; and to top it all at 'Jack Daniels' Distillery'!!

Being whiskey connoisseurs, we decided to take a stop at Lynchburg, Tennessee to witness how the world's largest selling whiskey is manufactured. The hour long tour taught us about the origins of 'JD', the myth behind the 'No. 7' brand, the manufacturing process and how a single distillery produces all the whiskey that is available in 135 nations globally.

Amidst all the information, the one that stuck with me was how 'lean' their manufacturing process is. It all begins at the 'Rickyard' where the charcoal for distilling the whiskey is prepared by stacking wood into "ricks" and carefully burning it. The secret behind this process has been passed along generations and it is this charcoal, which is later used to mellow the whiskey, that gives JD its unique smooth taste.

The next stop is the "Cave Spring" which is a source of natural iron free spring water which was discovered by Mr. Jack. This was the main reason why Jack setup the distillery in Lynchburg nearly a century ago. The clear flowing stream of water is one of the main ingredients in the whiskey making process.

Next on the agenda is the "Copper Stills". Corn, Marley and Rye are mixed in a proportion which was laid down by Jack himself to form the mash which arrives at the copper stills. The mash is then treated with high pressure steam from the cave spring which vaporizes the alcohol from the mixture and it rises to the top of the still where it is cooled by copper coils to form a clearer and more potent 140-proof spirit.

Next on the agenda is the "Copper Stills". Corn, Marley and Rye are mixed in a proportion which was laid down by Jack himself to form the mash which arrives at the copper stills. The mash is then treated with high pressure steam from the cave spring which vaporizes the alcohol from the mixture and it rises to the top of the still where it is cooled by copper coils to form a clearer and more potent 140-proof spirit.The next stop is the "Charcoal Mellowing". The spirit from the copper stills is then mellowed using the charcoal prepared in the 'rickyard'. The whiskey is allowed to flow drop by drop through 10 feet of the specially prepared charcoal until it is good and mellow. This is what makes Jack Daniel's a smooth sippin' Tennessee whiskey instead of ordinary Bourbon.

The next stop is the 'Barrel House' where the whiskey is stored before it is bottled and sent to its destinations. Jack Daniel's makes its own barrels from high quality wood to avoid compromising on quality. Each barrel is carefully hand-crafted and is used just once. The barrels are then stored at different levels in the storage house where they will mature. Whiskey tasters taste the whiskey from each barrel personally to ensure consistency in flavor, color and taste. The levels at which the barrels are stored is a crucial factor in decided what kind of whiskey it will mature into and based on that it is sold as the 'No.7', 'Gentleman Jack' or 'Green Label'.

However, the most fascinating fact is how Jack Daniel's ensures zero wastage.

- The charcoal that is used for mellowing is replaced every 6 months and the used charcoal is sold as souvenirs at stores or sold to local businesses.

- The barrel which is used just once is then exported to Europe where other whiskey manufacturers use it for their whiskey storage. Some of the barrels also double up as thrash cans all over the distillery facility.

- The mash which is used for producing the whiskey is processed and sold as fodder to local farmers who use it to feed their cattle.

- The water is used for cleaning and irrigation purposes.

Has anyone else personally witnessed a Lean Manufacturing process?

Do you think the fact that JD uses manual wine tasters ensures Quality Control or does it actually hamper the manufacturing process?

I recommend you visit the facility which will help all of you appreciate the 'No. 7' a bit more next time you sip on one. But don't keep your hopes too high of getting a free sample at the end of the tour. Lynchburg, sadly, is a dry county !!

Cheers....

Monday, November 28, 2011

The Challenges that come along with Lean Manufacturing

The concept of Lean Manufacturing has certainly transformed the way Supply Chain Management was perceived. It brought in strict measures inside the supply chain that eliminated all entities that did not add value to the customer. There has been extensive research to understand how Toyota was successful in implementing its Lean Manufacturing technique and many organizations have tried to mime their process. However, I always wondered if such a system could be so effective and wanted to probe on what kind of challenges that such a system brings in with itself. The research did throw some light on some interesting issues that gave answers to my questions.

Any system is free from being flawless and the Lean process was no exception. The system had its own share of criticism and was claimed by some, as the reason for the infamous Toyota recall in 2010 due to the sticking accelerator pedals issue. I was curious to know if Toyota's over focus on lean process turned out to be an obsession that blinded them from looking at quality aspect of production. Deep research and post-mortem of this issue has indicated that the lean process was not cause of the trouble for Toyota while it was observed that in the last few years Toyota failed to follow many of the principles it contributed to developing previously, resulted in the crisis. However, people still blame the lean process for Toyota's ultimate debacle, which the company is working to recover from. Will this leave a scar in people and prevent them from innovating?

An interesting question that I wanted to find answers for was whether such a practical principle can involve innovation, or would the disciple and rigor involved in the system, hamper the innovative thoughts. Can lean co-exist with innovation? The TPS case study touched upon the challenges involved in suggesting ideas to improve process. Any process improvement recommendations would have to go through the entire chain and will need the blessing of the group before it is put into practice. An interesting thought that came across was whether this really discouraged employees and stop them from innovating. "According to experts at The Boston Consulting Group (BCG) and Wharton faculty, lean and innovation can indeed complement each other, and it's about time they came together. Lean brings structure and predictability to innovation, and sharpens the distinction between idea generation and the development process, they say. Both share a common goal: to meet customer needs in a cost-effective manner. And lean can help empower researchers and reduce uncertainty in the innovation process itself"1. Best living example for this was the success of Hollywood animation company Pixar, the maker of blockbuster movies including the "Toy Story" series and "Finding Nemo," which embraced lean process but also made sure that innovation continued to flourish. The company is able to create a situation where projects that are likely to fail are eliminated early on. The involvement of the people of the company determines how well this system leads to a business transformation

Talking of the people part of things, it is a given that the success of a system in an organization ultimate depends on how well it is embraced by every individual in the firm. Toyota's lean process was a huge success for it was appreciated by every employee and it became a part of the company's DNA. Many Companies that tried adopted a similar system failed miserably as they tried to force it into employees when it was not appreciated well. “First of all, executive management must be committed to lean. If lean is a “grass roots” effort, it will have limited success. This is because lean involves so much of the organization. It involves procurement, manufacturing, quality, sales, marketing', and human resources. Each of these organizations will need to participate in the transformation. Therefore, the executives must want it. They must believe that it will improve their bottom line.”3. This might result in ultimate failure of the system. Communication plays a very important role here as the success of the system relies heavily on how the message reaches the employees. “An organization has an increased likelihood of initial and sustained success as a lean enterprise. Lean is not something that an industrial or manufacturing engineering group does to an organization; it is a cultural change. The importance of developing a foundation for this cultural change is critical to the success of any organization that begins a lean journey”3.

Though we all know that Change is the only thing that is permanent, we also are aware of the fact that Human beings resist change. I would love to hear your thoughts on how lean manufacturing can be adopted by a company, right from scratch and how it will tackle potential threats of employees carrying the fear of no room for innovation and the challenges involved in sending the right message

Credits

1. http://knowledge.wharton.upenn.edu/article.cfm?articleid=237

2. http://www.smartplanet.com/blog/business-brains/toyotas-pedal-troubles-result-of- too-much-or-not-enough-lean-manufacturing/4763

3. http://www.emsstrategies.com/dd073103article.html

Even Without Two Turntables or a Microphone, Reverse Logistics are "Where It's At"

Reverse logistics appears to be all the buzz these days, as many firms look to expand their supply chain beyond the traditional one-way flow that ended when a product got to a consumer's hands.

DIESL, the logistics arm of the Tata Group we discussed in class, has announced it will begin placing a greater focus on reverse logistics across India in order to complement its current supply chain services. The effort is a part of the company's overall commitment to environmental responsibility, and executives expect that this renewed focus will help minimize overall costs for reverse logistics as well as maximizing value from returned items.

In the United States, Ryder System, Inc. (a name you may recognize from its seemingly omnipresent fleet of moving trucks) recently announced it would be expanding its reverse logistics capabilities to include co-location solutions. According to the announcement: "By co-locating the distribution management of finished goods with returns processes such as technical repair, refurbishment, and repackaging in the same facility, this solution offers companies the ability to achieve greater speed to shelf, visibility, and cost-savings." In plain English, this is actually similar to the Dell technicians (if I remember correctly) who could operate out of FedEx's distribution hubs, as mentioned in class. So the idea is not a new one, but it does appear that Ryder is opening those capabilities up to a much wider range of clients.

Specifically, co-location as a part of reverse logistics can help a company with its sustainability goals, reduce its carbon footprint, save money on fuel costs and reduce total inventory levels through a quicker turnaround of returned product. (This is especially critical in high-tech industries where product life-cycles tend to be short.) The environmental impact of reverse logistics is so pronounced, in fact, that Steve Sensing, Vice President and General Manager of Hi-Tech/Electronics for Ryder Supply Chain Solutions said: "An effective reverse logistics strategy is actually the ultimate recycling process."

Question: do you find the environmental or financial incentives from developing an effective reverse logistics program to be more compelling? Why?

The Reverse Logistics Association

Zappos after the Case

The case authors were correct in saying that 2008 would be a challenging year for Zappos.com. Even though the company was able to reach their projected sales figure of $1 billion, they had to lay off eight percent of their employees. For most companies this would merely be a casualty of doing business in lean time, but for Zappos.com it was a hard pill to swallow since the company is so geared towards creating a good experience for their employees and thereby their customers. This can be seen in the two previous links as well as other posts on the CEO/COO blog (which is a great concept on its own for keeping employees and customers "in the loop" and is a great illustration of the company's transparency policy).

It seems that in order to better serve their customers while facing the economic realities of decreasing growth, Zapos.com moved towards greater automation in their warehouse facilities, as the case mentions. The authors talked about the use of conveyors and carousels, however I found this video that better details how the company began to use Kiva warehouse robots in 2008. The robots (and the Kiva system, in general) seem to allow the company to fill more orders, in a shorter amount of time with less people. In other words, this was another way they were able to give their customers better service by creating efficiencies in and dealing creatively with their supply chain.

What is perhaps most interesting, is that despite the economic downturn and market conditions of 2008, Amazon.com acquired Zappos.com for a reported $1.2 billion in 2010. As part of the acquisition or merger, depending on your point of view, Zappos.com was able to ensure that all of their employees would remain on board, the leadership would remain in place, and they would have the freedom to operate as a separate entity under the Amazon.com umbrella. While these seem like lofty expectations for a merger, it seems that after one year Amazon.com has honored the agreement.

It is worth noting that Zappos.com, as the case alluded to, did end up creating an outpost in Canada. However, they had to close the Canadian operation this past March. It seems that some of the sales agreements and other factors precluded the company from being able to offer Canadian customers the same level of service Zappos.com wants to exemplify.

So it seems rather than expanding to other countries, Zappos.com has focused on its ability to create an exceptional customer experience and exceeding the customer's expectations to grow the business moving forward. In fact, you could even argue that by merging with Amazon.com, Zappos.com has been able to focus even more on the customer experience while utilizing Amazon.com's ability to reach new customers. Do you feel this is the right approach or should they have chosen to focus on other initiatives like the "Powered by Zappos.com"? And does keeping with this approach adhere too closely to the corporate culture to the detriment of expanding the business in other ways (e.g. closing the Canada operation)?

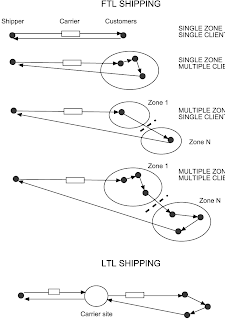

Less than Truckload (LTL) Shipping: A Middle Ground

When we think of shipping, a couple things come to mind:

The full shipping truck hauling heavy long-distance freight, or

The UPS truck delivering light freight and parcels

It doesn't occur to us, however, that there is any room in between. However, think about it: are there occasions where you'd want to send something over a hundred pounds, but not exactly enough to fill a whole truck? Aren't there business out there that would like to have equipment in the range [90, 16,000] pounds shipped to them from anywhere without incurring the cost of either large parcel post or whole truckload?

That's where Less than Truckload (LTL) technology steps in. LTL is like the baby bear's porridge from the story of Goldilocks: not too hot, not too cold, but just right. It seeks to meet the needs of mid-sized shipping, primarily in the B2B realm.

What is LTL?

LTL is characterized by the fact that it is a hybrid between full Truck Load (TL) and Parcel delivery services. Instead of delivering a large shipment in bulk or many different, individual parcels, LTL consolidates shipments in single pallets by destination, allowing for delivery to concentrated sites. Typically, the packages are delivered to a central distribution center and then sorted by area/destination. Sound familiar? LTL echoes the lessons learned from the Dabbawallas: other transportation methods can bring the goods to a distribution center so that a truck can pick them up. Hub-and-spoke methodology is critical to the success of LTL.

Great, but does LTL really improve the supply chain?

Although LTL sounds great to a certain segment of consumers, its usefulness has been marred by legislation (and this is the first time in this class that regulatory impact has come up). Under the 1980 Motor Carrier Act and the Trucking Industry Regulatory Reform Act, interstate trucking rates and routes were no longer regulated. According to the Bureau of Transportation Statistics, the result was that collusion between trucking companies became widespread due to the subsequent mergers and acquisitions that occurred (in favor of driving down aggregate costs for the participating firms). Because many of the providers operating LTL services were unionized, it was difficult for consolidated firms to rely on them rather than cheaper TL services, so the importance of LTL was diminished.

This shouldn't get us down though. The need to shorten supply lines and thus the logistics cost per unit of shipping requires SCM practitioners to be vigilant about how they can better organize their shipping behavior. After all, supply chain operating costs are a top concern for CFOs. While larger firms might exclusively use TL for their products due to inventory needs, they would do well to focus on the pallet-grouping behavior that LTL espouses. With forecasting methodology becoming more and more sophisticated as well as the occasional need for responsive inventories (read: Dell), knowing how to group shipments for maximum return on shipment is key to transportation strategy.

Just like how Ikea made sure their inventory was flat so it could fit inside one cargo container, firms would do well to figure out the optimal use of their trucking fleet, whether it is in-house or outsourced.

Sunday, November 27, 2011

TRANSPORTATION IN LOGISTICS CHAIN

Since logistics advanced from 1950s, there were numerous researches focused on this area in different applications. Due to the trend of nationalization and globalization in recent decades, the importance of logistics management has been growing in various areas. For industries, logistics helps to optimize the existing production and distribution processes based on the same resources through management techniques for promoting the efficiency and competitiveness of enterprises. The key element in a logistics chain is transportation system, which joints the separated activities. Transportation occupies one-third of the amount in the logistics costs and transportation systems influence the performance of logistics system hugely. Transporting is required in the whole production procedures, from manufacturing to delivery to the final consumers and returns. Only a good coordination between each component would bring the benefits to a maximum.

The Effects of Transportation on Logistics Activities

Transportation plays a connective role among the several steps that result in the conversion of resources into useful goods in the name of the ultimate consumer. It is the planning of all these functions and sub-functions into a system of goods movement in order to minimize cost maximize service to the customers that constitutes the concept of business logistics. The system, once put in place, must be effectively managed.

Traditionally these steps involved separate companies for production, storage, transportation, wholesaling, and retail sale, however basically, production/manufacturing plants, warehousing services, merchandising establishments are all about doing transportation. Production or manufacturing plants required the assembly of materials, components, and supplies, with or without storage, processing and material handling within the plant and plant inventory.

Merchandising establishments completed the chain with delivery to the consumers. The manufacturers limited themselves to the production of goods, leaving marketing and distribution to other firms. Warehousing and storage can be considered in terms of services for the production process and for product distribution. There have been major changes in the number and location of facilities with the closure of many single-user warehouses and an expansion of consolidation facilities and distribution centers. These developments reflect factors such as better transport services and pressures to improve logistics performance

The Role of Transportation in Service Quality

The role that transportation plays in logistics system is more complex than carrying goods for the proprietors. Its complexity can take effect only through highly quality management. By means of well-handled transport system, goods could be sent to the right place at right time in order to satisfy customers’ demands. It brings efficacy, and also it builds a bridge between producers and consumers. Therefore, transportation is the base of efficiency and economy in business logistics and expands other functions of logistics system. In addition, a good transport system performing in logistics activities brings benefits not only to service quality but also to company competitiveness.

Reverse Logistics at Zappos

Easy return is the key to e-commerce, especially when it comes to shoes. There's always anxiety once order is placed: will it fit? will the color be right? will it be comfortable? The disappointment a customer experiences when the shoes arrive would keep the customer from shopping for shoes on-line. When Zappos made the return process easy, customers will not shy away from ordering multiple colors and sizes for fit and return part of them later.

Just as how the Dabbawallas return the tiffins, the return process at Zappos is also handled by UPS, who made a small video about the service here.

The return process go through similar as the forward one; the only difference is perhaps that customers drop most of the packages at UPS locations. As it says in the case study, about 25% of the orders are returned.

It is interesting then, to think about whether such process is applicable for another type of reverse logistics, recycling. The difficulty lies in the fact that the recycled products have little value to the producers. In addition, for retailers like Zappos, there's an additional process of sending the recycled products back to the producers. Or as Zappos expands from on-line retailing to managing logistics and warehouses, should they tap into the recycling business?

More about reverse logistics from Fleischmann, M, Bloemhof-Ruwaar, J.M., Dekker, R., van der Laan, E., van Nunen, J., Von Wassenhove, L.N. (1997) Quantitative Model for Reverse Logistics, A Review. European Journal of Operational Research,103,1-17. Retrieved from www.elsevier.com.

Wednesday, November 23, 2011

Don't Buy, Lease.

- Leasing trucks is a form of risk mitigation. It turns transportation into a somewhat fixed cost, and saves your business capital that can be used elsewhere. (Which would be great since one of our food purveyors is opening a market/stand in Pittsburgh) In addition, there are rarely down payments on leasing vehicles.

- Leasing companies take care of maintenance. Some even offer road-side assistance. This means that a food and beverage business can focus on what they're supposed to focus on - food.

- No depreciation on the balance sheet. If anything, leasing a trailer will merely be a footnote in a company's financial statements. And, moreover, a company will usually have access to newer equipment.

- Newer equipment and better regulating technology means that a company will be better able to control for refrigeration and gasoline costs.

Tuesday, November 22, 2011

Green Supply Chain Network: How IT helps?

Patrick Penfield of the Whiteman School of Management defines Green Supply Chain Management (GSCM) as "the process of using environmentally friendly inputs and transforming these inputs into outputs that can be reclaimed and re-used at the end of their lifecycle thus, creating a sustainable supply chain.”

With increasing customer awareness and regulatory norms, organizations with greener supply chain management practices will have a competitive advantage over companies that are reluctant to embrace GSCM. Hence across industry there is a shift in the focus of GSCM programs from compliance to creating value for customers and shareholders.

There are several good examples:

- Dell saves over $20mn annually as a result of supply chain and packaging improvements. In fact, this market leader achieved its goal of becoming carbon neutral by 2008

- Texas Instruments saves $8mn each year by reducing its transit packaging budget for its semiconductor business through source reduction, recycling, and use of reusable packaging systems (20% annual savings)

However, implementing GSCM has never been easy. Organizations are likely to face certain challenges some of which include:

- Lack of information about the green supply chain best practices

- Lack of tools to optimize the supply chain with environmental management

- Global sourcing making tracing of carbon footprint difficult

Contributions of IT in GSCM can be viewed from two different perspectives, one is from hardware and one is from software.

- From hardware perspective, IT helps to optimize hardware resources to support business by right-sizing IT infrastructure, re-architecting data processing and storage operations, leveraging shared infrastructure and adopting a lifecycle approach to the retiring of IT waste.

- From software perspective, IT helps streaming and transforming business processes by better planning, executing, and collaborating green supply chain.

Mexican Trucks and Canadian Pipes

The Keystone XL Pipeline is a relatively new issue in the United States media but allow me to fill you in. In essence it is a pipeline that will carry Canadian crude oil from the Athabasca Oil Sands in Alberta to various areas in the United States. A map is found here. The proposed extensions

in yellow are two different phases. This is where the controversy lies. There are questions over the necessity of such a pipeline and the environmental impacts(carbon, water, etc.) There is dissension from other OPEC nations like Nigeria and Venezuela. As we have learned in class, pipelines carry large fixed costs. There is steadily increasing demand from BRIC that is outstripping supply. Prices rise. I feel it is a worthwhile endeavor. If you put your policy caps on for a moment, what do you think? Are the potential environmental impacts enough to outweigh an improvement in our energy supply network?

in yellow are two different phases. This is where the controversy lies. There are questions over the necessity of such a pipeline and the environmental impacts(carbon, water, etc.) There is dissension from other OPEC nations like Nigeria and Venezuela. As we have learned in class, pipelines carry large fixed costs. There is steadily increasing demand from BRIC that is outstripping supply. Prices rise. I feel it is a worthwhile endeavor. If you put your policy caps on for a moment, what do you think? Are the potential environmental impacts enough to outweigh an improvement in our energy supply network?The Mexican Trucking program has its roots in the North American Free Trade Agreement

(NAFTA) of 1993. Part of the original agreement was a provision that allowed for Mexican trucks to travel to any destination in the United States and then back to Mexico. After 15+ years of retaliatory tariffs, political wrangling, and environmental challenges, a pilot program was started this October. I believe this will help the logistical issues on the HUGE 3,169 km (1,969 mi) border. The Mexican trucks that are not part of the pilot have to unload their merchandise at warehouses near the border for US truckers to pick up. An article relating to this issue quotes a Senior Fellow at the Petersen Institute for International Economics on the extra costs this entails:

(NAFTA) of 1993. Part of the original agreement was a provision that allowed for Mexican trucks to travel to any destination in the United States and then back to Mexico. After 15+ years of retaliatory tariffs, political wrangling, and environmental challenges, a pilot program was started this October. I believe this will help the logistical issues on the HUGE 3,169 km (1,969 mi) border. The Mexican trucks that are not part of the pilot have to unload their merchandise at warehouses near the border for US truckers to pick up. An article relating to this issue quotes a Senior Fellow at the Petersen Institute for International Economics on the extra costs this entails:"It's probably 3, 4, 5 percent. It depends on the kind of product you're shipping."Talk about inefficient. The Laredo, TX border crossing alone handles 40% of merchandise by volume and 50% by value that are coming into the United States. This is according to a study of the International Journal of Transport Economics. The Nogales, NM crossing handles 2/3's of the winter produce coming into the United States in Canada during winter. These are critical nodes in our macro supply chain. Anyway to logistically streamline the transport of goods across the border is a welcoming change IMO. Slide 19 in the Week 5 slide deck shows how dire things are. We are rapidly approaching gridlock. Not all is good however. With the increasing border violence spilling over into the US, the illegal drug trade, and illegal immigration people are right to be concerned. There are legitimate security and economic risks. Again, I ask you to put on your policy caps. Do you see this as a step forward or does it invite more risks to the international supply chain between two nations?

Saturday, November 19, 2011

Quality and Risk in supply chain management

Poor quality products, an unsafe work environment, or failure to comply with regulations ranging from product safety to social responsibility, can cause business disruption, financial loss, costly lawsuits, and long-lasting damage to the brand and corporate image of organizations that are dependent upon supply chain vendor performance. In the extreme, a brand, or even a company's reputation, can be damaged irreparably.

The crisis-catalyst may originate during any step in the supply chain process, from design to raw materials, to production, or transportation. Most often the issue centers on substandard materials or how well components or finished goods were designed and produced. Recently, company reputations have been damaged by substandard social responsibility practices of suppliers, even when the product quality was acceptable.

The quality management policies and practices of suppliers must be aligned with the standards of the company branding or selling the product. These quality management practices should also be aligned with accepted international standards. This is because failures in the supply chain are passed down the line to the firms ultimately marketing the products. Such failures can result in consumer dissatisfaction, regulatory noncompliance and, in some cases, public criticism of the corporate management practices.

There have been numerous, highly publicized cases in recent years from tainted toothpaste to lead paint in toys, to flawed labor practices of manufacturers. Companies are increasingly setting standards of quality management systems and worker treatment for their suppliers to avoid these kinds of problems. Vendor quality management standards are increasingly becoming a contractual condition for maintaining a supplier relationship.

Meeting stricter client and international quality management standards requires some vendors to invest in improving practices, policies, and management systems. Many adopt international standards, especially those of the International Organization for Standardization (ISO), the American National Standards Institute (ANSI), and the American Society for Quality (ASQ) to demonstrate acceptable practices. Additional security standards also may have to be adhered to by transportation, shipping, and logistics firms in the supply chain. While improvements in performance require investment, there are compelling benefits for suppliers to move forward. Adherence to quality management standards differentiates suppliers from competitors who don’t comply and strengthens the relationship between a company and the vendor.

Companies should periodically validate vendor adherence to the required quality management standards by conducting supply chain vendor audits. Audit protocols serve an additional critical role, namely that of identifying and qualifying new vendors. The validation process involves on-site vendor audits that compare actual vs. required policy and practice standards. These analyses enable identification of critical performance gaps and opportunities for improvement. Constant improvement in quality management helps to reduce the risk of costly and embarrassing failures.

Audits help to build confidence that risk is being properly managed. Through these audits, companies can evaluate the quality of a product and compliance with applicable regulatory requirements. Additionally, one can assess adherence to process-management, social and environmental accountability, and workplace health and safety standards. However, this all comes at a cost. Supply chain audits can be time-consuming, require on-site inspection teams, and are most effectively done by designating a full-time, product-knowledgeable team to the effort. Further, vendors are often geographically remote and audit criteria can become culturally complex. These factors can seriously challenge even well-staffed quality management functions, and be virtually impossible to conduct effectively for organizations that are constrained by staff and budget limitations.

Thursday, November 17, 2011

Lean in Software Development

Such a meeting involved a Scrum-master, who is a facilitator of the meeting and all the team members who were required to give answers to three questions in less than a minute