Global supply chains are becoming more and more complex. It has become significantly important to leverage and integrate technology into the supply chain. There are quite a few reasons for the same - the in-transit visibility in a supply chain where a lot of parties are involved in the logistics has some latency, the fluctuating demand has made it difficult to approximate the optimal inventory level, customers want product delivery on their doorstep in a very short period, etc.

A couple of disruptive technologies that can have a tremendous impact on various stakeholders in the supply chain are:

1- Internet of Things(IoT)

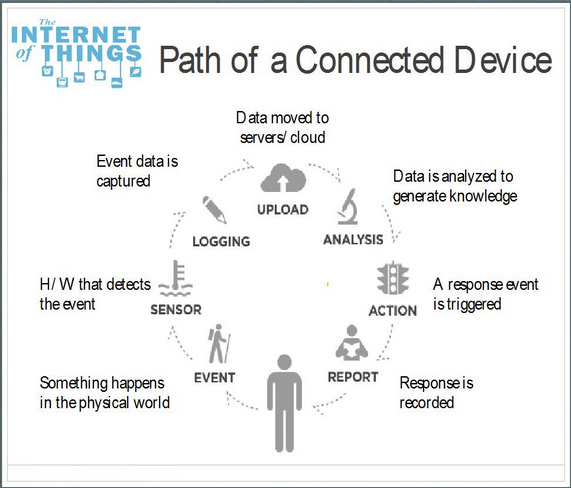

Sensors and devices connected to the Internet “talk” to each other automatically, without a conscious intervention. Data is automatically transferred, analysed by programs/models and the results may be used to trigger appropriate event(s).

According to Cisco, there will be about 50 billion connected devices in 2020, up from about 18 billion devices currently. These devices can collect a huge amount of data and analyse the information for entire processes. Some implementations already in place include commercial telematics for trucking fleets, smart homes, smart parking etc. More implementations for various industries like manufacturing, healthcare, textiles etc. are being developed recently.

Few areas of supply chain where IoT can play a major role includes:

i - Enhanced in-transit visibility

Home depot, for example has a hard time getting information about where its containers are on a vessel and when those containers will be offloaded. They need that information to get proper resources such as drayage and labor in place. Also, they need to estimate when they will get stock of a particular product so as to give an accurate delivery estimate to customers.

Using a combination of devices such as RFID, GPS and an internet communication channel, one can find out things like the exact location of product, the ambient temperature etc. This can provide a lot of value to the supply chain. For example, a company called Purefresh dealing with perishables extensively utilises IoT to provide tracking of environmental factors like temperature, ozone etc. and also provides the ability to optimise delivery routes to provide maximum freshness. According to their estimations, about 30-50% of the food is lost in transit.

ii - Replenishment

IoT can aide with proactive replenishment with little or no human interaction. For example: smart vending machines - it can know when it is running low or out of stock on some product and can send a reorder request automatically to the supplier’s machine. This can save a lot of time and human effort by getting rid of the non value adding task of physically checking the stock of each product in the vending machine.

iii-Maintenance

Sensors in machineries and different parts are a huge source of different kinds of data. This kind of data can help with predictive maintenance. In places such as oil and gas plants etc. it is of utmost importance as “prevention is better than cure” in all situations. A minor glitch can result in catastrophic outcomes. A platform can be setup with data collection layer on the bottom-it collects the huge amount of data from hundreds of sensors, sensing layer in between-it segregates important information and extracts useful and relevant patterns/signals from the data and the response layer on the top-it helps understand the signals/patterns from a higher level(visually or otherwise).

But there are still more steps to be taken to take IoT at a higher level - standardisation of IoT protocols being the most important step in this direction. After all, standardisation is the key to any widely accepted technology.

2- 3D printing

There’s not much that 3D printers cannot print these days-printing vases, fuel nozzles for airplanes, guns and even entire houses is a reality these days. It has all the potential to revolutionalize supply chain by changing product development and lifecycle management. It can benefit stakeholders including manufacturers and retailers. For example, a car company, instead of keeping a large inventory of screws or running out of screws can use 3D printing on site to “print” screws as and when needed. As economies of scale sets in, it can save lots of money on shipping.

3D printing can also give rise to highly customisable products because creating such products will not require setting up machines again; it will only require a little tweak in the software. If a customer wants a black colored phone case or if another customer wants a white colored phone case, with a click of a mouse, you can print either!

This will positively impact stakeholders in the supply chain who struggle with maintaining appropriate inventory levels, whether high or low. On the other hand, it will negatively impact stakeholders which are the suppliers of these items. The ability of skilled manufacturing that has made China such a huge manufacturing hub will lose its value.

Even Amazon has a few personalised 3D printer products to offer like necklaces, bobble heads, wallets etc. As the technology is developing, the cost of the hardware is reducing considerably. An industrial scanner now cost no more than a few hundred thousand dollars whereas a retail 3D printer would not cost more than a few thousand dollars.

But, along with a plethora of benefits and a tremendous increase in efficiency that 3D printing brings to a variety of domains including supply chain, it also brings quite a few concerns; especially security. There have been quite a few instances of people printing guns on a 3D machine. It has a potential of wreaking havoc.

There are a lot of other technologies that have a potential to impact supply chains in a revolutionary way. We’ll just have to wait and see which technology is able to survive for long and is accepted by masses.

References/Sources:

· http://www.supplymanagement.com/news/2014/internet-of-things-will-significantly-alter-supply-chains

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.