"You kind of

want to manage it like you're in the dairy business. If it gets past its

freshness date, you have a problem" says Tim Cook, CEO of Apple Inc.

Albeit not really a “product

visionary” like his predecessor, Tim Cook more than makes up for it with his

impeccable inventory management and operation skills. In 1998, when he joined

Apple Inc. as Head of Operations, the distribution of the company was a mess. One

of the major steps taken by Cook and Jobs initially was to exit the

manufacturing business and begin outsourcing the production. A bold move, one

would say, considering Apple was going through a decline in revenues and dwindling

profits made it harder to invest in new ventures. Accumulated inventories worth $1,775 million

were lying around in Apple warehouses in 1995.

Another step,

bouncing off the outsourcing the manufacturing, was to cut down on the number

of component suppliers from 100 to 24, a masterstroke in hindsight. It made companies

compete for Apple’s business and gave Apple leverage in component pricing

negotiations. Additionally, warehouses were reduced from 19 to 10. He focused

on cutting down the inventory in a big manner and by the end of his third

quarter at Apple, the inventory was down by 80%! Cook’s strategy of “slash inventory, shut warehouses, run manufacturing close to the

bone” worked wonders for Apple and immediately had Steve Jobs looking at Tim

Cook to succeed him. In 1998, Apple Inc’s profits rose to $309 million,

compared to the $1045 million loss it made two years ago. The Macintosh was a

particular gainer of this strategy, and Cook cut the production process for

making an Apple computer from four months to two.

Today, although most

people credit Apple’s success to their revolutionary products, few know that a

key role in it becoming a leader is its exceptional inventory management. A study

released by Gartner shows that Apple turns over its inventory about 74.1 times

a year, which is once every 5 days.

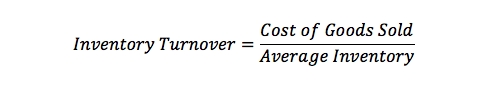

In terms of “Inventory

Turnover” (indicates how many times the current inventory could be sold and

replaced in a certain period) The higher the Inventory Turnover, the

better.

A second

indicator is “Days of Inventory” i.e. how many days would it

take for a company to sell off all its inventory. In other words, it is the

amount of inventory that a company holds. The lower the Days of Inventory, the better.

In terms of both

these vectors, Apple rules the roost. Dell comes in second despite the fact

that it prides itself as working on a build-to-order model.

Having inventory on

the shelf is of little use to a corporation. It loses its value (about 1 to 2 %

every week) and eventually needs to be discarded. Learning from the case of Apple

and Tim Cook, we can conclude that efficient supply chain management is key to

companies reducing avoidable costs and in turn increasing profit margins.

REFERENCES:

2) http://cporising.com/2012/09/19/the-strategies-that-propelled-tim-cook-from-cpo-to-ceo-1/

3) http://appleinsider.com/articles/12/06/18/under_tim_cook_apple_cracking_down_on_supply_chain_management

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.