Apple: Inventory

Management

Apple is widely

known for innovation and design, however few people understand Apple’s success

is framed around how they handle inventory. In fact, Gartner – the word’s

leading IT research and advisory company, ranks Apple’s Supply Chain as the

best in the world between the years 2010 and 2013.

Tim Cooks (the

current CEO of Apple) believes that when it comes to technology products, such

as laptops, tablets, and smartphones, inventory depreciates very quickly,

losing 1-2% of value each week. He quotes, “inventory is fundamentally evil… you

kind of want to manage it like you’re in the dairy business. If it gets past

its freshness date, you have a problem.”

Cook’s vision

helped Apple ascertain technological breakthroughs; over 37 million iPhones

sold in Q4 of 20111 displays highly successful inventory management.

Previously, Dell had been the front-runner of a ‘make-to-order’ model, however Apple

is currently the dominant market leader when it comes to running inventory.

Inventory

Turnover and Days of Inventory:

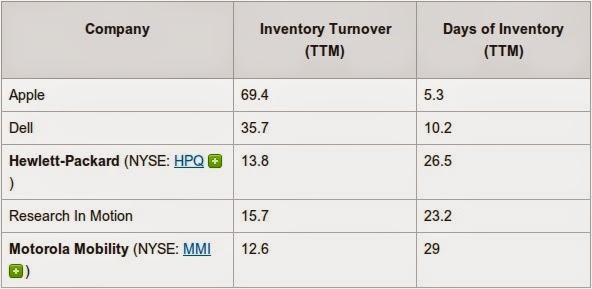

To measure this

success, analysts typically use two indicators: Inventory Turnover, and Days

of Inventory. Inventory Turnover shows how many times the current inventory

balance of a company could be sold and replaced over a specified time period

(the higher the number, the better). The formula is as follows:

Days of

Inventory is a similar metric, which displays how long it would take for a

company to sell through all of its inventory. It simply indicates how much

inventory a company holds; the lower the number, the better. The formula is as

follows:

Reviewing

historical data, Apple has been viewed as extremely efficient with its

inventory. Often, when a customer orders online, the product is shipped

directly from China (so Apple doesn’t even have to look at it). When demand

increases substantially, for example – during a new product release, Apple

reacts quickly with massive hiring sprees at Foxconn. See Figures 1 and 2 below

for data on Apple’s highly efficient inventory management.

Apple Supply

Chain Operations:

Essentially,

Apple purchases necessary components and materials from various suppliers;

subsequently, they get shipped to the assembling plant in China. From there,

Apple’s products are shipped directly to consumers who purchased from the

online store.

For other

distribution channels (i.e. retail stores and other distributors), Apple keeps and

ships their products at the central warehouse and call center located in Elk

Grove, California.

Apple

Inventory Management:

Cook’s strategic

goals from day one as the new CEO was to slash inventory, cut down on

warehouses and make suppliers compete between each other. In 2012, Apple was

said to effectively turn inventory every 5 days (another reason for Gartner to

place Apple’s supply chain as best in the world).

Keeping minimal

inventory is crucial because of warehouse costs and competitors. Technology

manufactures are simply unable to afford to keep too many products in stock; a

sudden announcement from any competitor or new innovation may change everything

and suddenly bring down the value of products in inventory.

Closing

Comments:

It is true Apple

pushes to have fast inventory turnover; however, it seems in 2011, it made a

change of not rushing selling. This change came with the launch of the iPad 2

and consisted of selling the products the second day after they were delivered

to shops. Was this measure created to ensure smooth inventory tracking and

little to no errors of inventory inaccuracies? Moreover, is inventory

management Apple’s true secret their Supply Chain success?

Sources:

http://www.gartner.com/technology/about.jsp

http://www.phonearena.com/news/Apples-secret-sauce-for-success-is-inventory-management_id28558

http://blog.tradegecko.com/apple-had-the-best-supply-chain-in-the-world-for-the-last-four-years-here-is-what-you-can-learn-from-it/

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.