Various

programs exist, such as Six Sigma, Lean Thinking, and the Theory of

Constraints, that all help businesses improve performance by decreasing inefficiencies.

Typically, these types of programs were created for heavy manufacturing

operations such as Toyota’s vehicle assembly line.

After showing

success in manufacturing, the same programs have been tried in service

industries as well. Starbucks has had an increased number of daily transactions

at stores implementing an improvement program, and therefore, is making more

money [1]. Seattle Children’s Hospital has decided not to spend millions of

dollars on an expansion project to care for more patients after implementing an

improvement program that increased the hospital’s capacity by reorganizing

their resources.

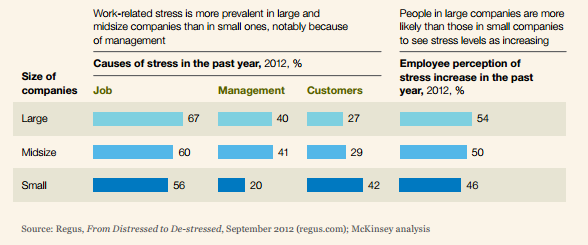

Improving

operations on a manufacturing line is one thing, but many argue forcing coffee

baristas and hospital nurses to cater services in the most efficient way

possibly greatly detracts from customer and patient care. One study done by

McKinsey published in “The Lean Management Enterprise” shows that employees of

larger organizations become more stressed when there is more management as seen

in figure 1 [3]. Managers implementing and enforcing improvement programs can

be a major source of stress for employees as mundane tasks such as creating a Frappuccino,

or starting an IV are timed by the second.

Figure 1.

It is

important to consider whether an employee in the service industry can provide

the same level of customer care when so much pressure weighs on them to run the

most efficient operation possible. One nurse argued that “procedure times can’t

always be standardized. For example, some children need to be calmed before IV’s

are inserted into their arms” [4] Therefore, supporters of improvement programs

need to consider the tradeoffs that exist when employees are urged to operate

more like robots and less like compassionate individuals.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.