The Real Secret

Despite their perceived simplicity, Walmart has learned how

to successfully incorporate technology into their strategy, making their

business more efficient. It is often

thought that their ability to sell at such low prices comes from their size and

bargaining power over their suppliers.

Their real savings come from their well-organized supply chain, since it

benefits not only them, but their suppliers as well.

During the early stages, suppliers were hesitant to provide

information, concerned of compromising their own competitive positions. However, they have now adopted Walmart’s

system. Both store and supplier share

and integrate data so that they can have a better understanding of what

products sell. This enables the store to

keep its low storage prices and suppliers to adjust their production depending

on the demand (sales).

Moving Forward

Because they are almost considered an empire, Walmart can

afford to experiment and pioneer technologies that have not gone through deep

testing. This has helped them

restructure their business. They use

technology to simplify work and increase efficiency, besides automating

existing processes. Part of their

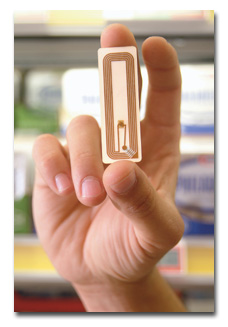

experimentation has been the implementation of RFID; they tag products (or

their labels) with tiny chips that emit radio signals to small receivers [2]. This technology was adopted with the

objective of making barcode scanning technology even simpler and more

efficient.

Is this the Right Move?

The use of RFID chips might increase as their price

decreases [3]. However, this technology has

yet to prove its value. There is concern

on security; can you imagine driving home and as you approach your driveway,

you’ve picked up information on how many rolls of toilet paper are in each of

your neighbors’ houses?

Maybe Walmart sees something we don’t; maybe they have

learned how to recognize and see potential in new technologies and they’ve made

sure that the mindset of “invest only in what will guarantee returns” is

embedded in every employee. Could it be

a cultural thing? I don’t know, but they sure do seem to be very aware of every

penny they invest, which leads to more intelligent decision making.

What’s the Panorama Like Today?

According to IDTechEx, RFID is rapidly growing for apparel

tagging [4]. Walmart continues to use

RFID, but they now asked their suppliers to put the RFID chips on the packaging

or removable labels, instead of the product itself, to address the security

issue mentioned before. Smart move

Walmart. The incorporation of RFID

enables them to locate and quantify merchandise faster than they could before,

which is an essential advantage for supply chain managers, and also drives

business value.

This is all very positive and nice, but I cannot let this

topic go under the radar. Since this is

the last blog, I now encourage the reader to be the one who challenges this new

trendy concept. Imagine being a supply

chain manager and having visibility to absolutely everything; how difficult (or

possible) would it be for this sole person to have control of all the

information being channeled to him/her? Do you think this could lead to a more

centralized -and difficult to control- chain management structure? Can we even

call it a “chain” or are we looking at a very complex supply network now?

References:

By: Elisa Taymes

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.