Game Changers

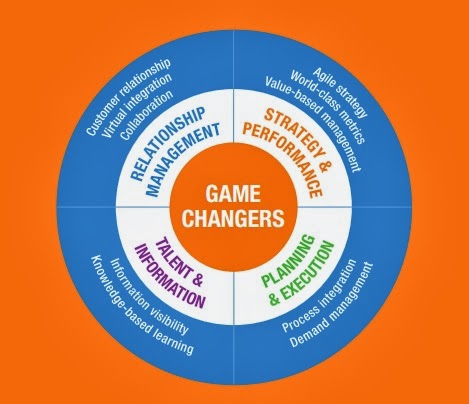

This blog will give you a brief synopsis of today’s leading thinking about the five game-changing trends in supply chain:

1. Customer service to customer relationship management

2. Adversarial relationships to collaborative relationships

3. Incremental change to a transformational agile strategy

4. Functional focus to process integration

5. Absolute value for the firm to relative value for customers

Game Changing Trends

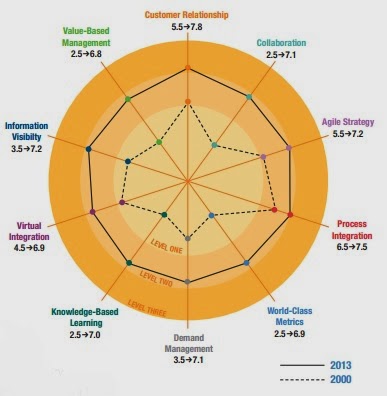

In the last two months of 2012, over 160 supply chain professionals were surveyed to assess these 10 trends in industry, as well as how those trends have changed. While they will be expanded in the body of the white

paper, below are some highlights of that survey:

- Firms have made significant and in some cases surprising progress in the last decade and in each of the 10 areas.

- Some companies have achieved top levels of performance in individual categories, although no firm has excelled in all categories. Thirteen years ago, no one reported a top level of performance in any category.

- There are laggards in each category as well. These firms appear to be fighting the same battles in the same way.

- Respondents feel that most progress has been made in customer relationships and cross-functional integration. Firms seem to be better focusing on their customers outside the firm and shoring up the emphasis on cross-functional processes inside the firm.

- Talent management clearly emerges as the linchpin required for advancement in all areas.The remainder of this white paper is divided into 10 sections, one for each trend. We have used the survey information as one input but also included the leading edge thinking from all of our research and industry contacts.

1. Customer Service to Customer Relationship Management:

Customer relationship management remains a game changer for all companies because it requires customer prioritization to maximize revenue and profitability by targeting limited resources. Few would disagree that

this needs to be done; yet we find that few companies actually create customer focused, differentiated supply chain plans. This requires tough choices that are sometimes unpopular and often engulfed in politics. But

a few leading firms have truly embraced this game-changing trend that is gathering momentum.

2. Adversarial relationships to Collaborative relationships:

Developing collaborative relationships with suppliers and customers is a game changer because so few firms really accomplish true win-win partnerships. But the few that do have experienced dramatic and even breakthrough improvements in product availability, cash flow, cost, and shareholder value. Supply chain professionals have been talking about collaboration for years, but unfortunately, as one executive lamented,

Developing collaborative relationships with suppliers and customers is a game changer because so few firms really accomplish true win-win partnerships. But the few that do have experienced dramatic and even breakthrough improvements in product availability, cash flow, cost, and shareholder value. Supply chain professionals have been talking about collaboration for years, but unfortunately, as one executive lamented,

“When all is said and done, there’s been more said than done.” Companies can achieve game-changing competitive advantage in this area by accomplishing what their competitors have failed to do.

3. Incremental Change to a transformational Agile strategy:

Our research shows that only 16% of firms have a documented, multi-year supply chain strategy at all...let alone an agile, transformational strategy. Yet the supply chain is the heartbeat of the firm, the prime driver of economic profit and shareholder value. Firms clearly must have a strategy to achieve a game-changing supply chain.

For example, in the Harvard Business Review article Leading a Supply Chain Turnaround the authors discussed the story of how Whirlpool implemented an agile, transformational strategy. The strategy served as the foundation for a true supply chain transformation and led to the following breakthrough results achieved by Whirlpool:

- Historic low inventory level, down almost $100 million

- Record high service levels

- Total cost down over $20M, ignoring inflation

- A major customer satisfaction improvement, with typical customer survey responses being

–“Whirlpool is most improved”

–“Whirlpool is easiest to do business with”

–“Whirlpool is most progressive”

– “Whirlpool is good now, but more importantly, they are consistently good.”

4.Functional focus to process integration:

Over the past five years, we have interviewed over 700 supply chain professionals during supply chain audits. Based on all of those interviews, we are absolutely confident that supply chain professionals recognize true cross-functional integration as a game-changing trend. In fact, when we ask the “wish list” question in our interviews, supply chain professionals don’t ask for more resources but instead pine for a company where the silo walls have come down. They intuitively know that this lack of cross-functional integration is a huge issue holding them back.

5. Absolute value for the firm to relative value for customers:

Can simply changing the performance measurement and goal setting system inside a firm significantly enhance the overall performance of the supply chain? You bet it can. Just as firms need a transformational supply

chain strategy, they need a metrics and goal setting system that drives the new behaviors required by the new strategy. The old phrase is still apt: “If you always do what you always did, you’ll always get what you always got.” We need a new metrics/goal setting system aligned with a transformational strategy to change the supply chain game.

For example, a large consumer packaged goods company felt they needed something that would break through the firm’s complacency, something that would propel them to a new level of performance. They developed the perfect order metric, calculated by multiplying together four factors for each customer order: on-time, complete, damage free, and invoiced correctly. Instead of basking in the glow of 95% performance in each category, they were stunned to see a new metric that showed an 81% level of performance (e.g. 0.95 x 0.95 x 0.95 x 0.95). This drove the organization to a totally new level in customer service, caused their competitors to scramble, and significantly increased market share and sales.

Conclusion:

Today, a small but growing number of companies are reporting that they leverage their supply chains to make working capital an cash flow improvements that drive economic profit and shareholder value. Future supply chain organization must focus far more than just driving out costs and improving product availability. Instead, they need to become an engine of overall financial improvement for their companies. Smart companies will use innovations in their supply chain to generate the cash to fund innovations in their product lines and growth in their business.

When the credit markets froze in 2008-2009, a few firms realized that they could free up cash internally without having to go to the banks. A study by Ernst & Young showed that $1.2 trillion (equivalent to 7% of their aggregate sales) is unnecessarily tied up in working capital across 2,000 of the largest companies headquartered in the United States and Europe.

A major lesson learned in our work with many firms is that this focus must be driven from the top of the company. Without strong, consistent support by the CEO, the CFO, and the COO, many initiatives cannot be successful due to the massive alignment of functional silos required. The fundamental learning from the case, surprising in its power, was how supply chain can be used as a lever to dramatically lower working capital and improve cash flow.Since these changes positively affect economic profit, investors reward these efforts as they realize higher shareholder value.

Question:

To succeed, must companies embrace Supply Chain Excellence as a core competency at all levels throughout the company and recognize that supply chain management is executed in many areas, not just the functional supply chain organization ?

Question:

To succeed, must companies embrace Supply Chain Excellence as a core competency at all levels throughout the company and recognize that supply chain management is executed in many areas, not just the functional supply chain organization ?

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.