Although no matter small, medium or large companies all over the world are benefitting from supply chain management, everyone is still struggling to succeed in overall supply chain system. In spite of lean manufacturing, just-in-time inventory and etc. which help improve the business performance, supply chain professionals are continuously facing old and new challenges and opportunities.

McKinsey Survey

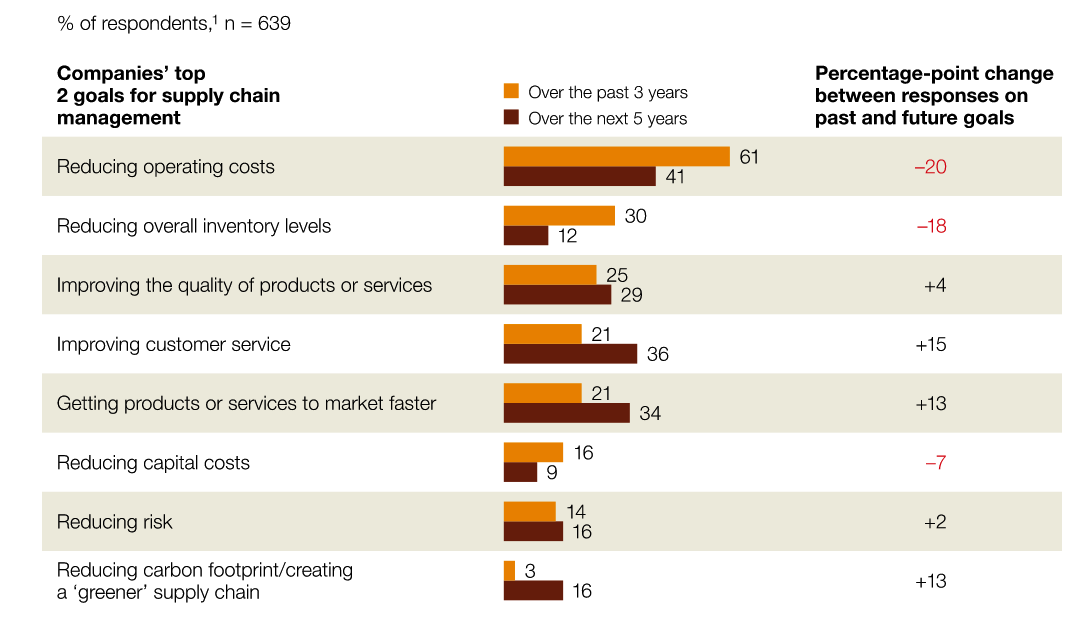

In 2010, McKinsey & Company conducted a global survey about the challenges ahead for supply chains. Here are some results:

The first graph shows companies’ challenge in supply chain management. Global competition, increasing complex patterns of customer demand, increasing financial volatility, increasing global labor market, and growing exposure to different regulatory requirements are becoming more severe in the following 5 years; volatility of customer demand, customer expectation about service and quality, cost pressure in logistics/transportation, and volatility of commodity price are still the main issues while their significance in the long run has declined.

The second graph shows companies’ top 2 goals for supply chain management. In the five year prediction, improving quality, improving customer service and the faster speed of getting products or service to market are becoming more important goals than in the 3 year prediction. After applying the advanced supply chain management tools, the future competition has shifted from merely reducing cost to more concentrating on quality and speed.

SCM World Survey

In 2013, SCM World conducted a survey of 750 senior supply chain professionals and concluded the five major issues that supply chain leaders are facing.

- The need to continue to reduce costs while improving customer service and supporting expansion in new markets and product lines.

- The need to manage the “complexity of ‘omnichannel’ selling and customer fulfillment”.

- The fact boards expect lower costs and greater efficiency

- Safety and quality incidents are at the top of the risk index

- The issues of facilitating career progression, developing new production skills and demonstrating a return on investment.

The two different surveys have shown similar challenges that supply chain companies are facing right now and in the future. Product quality, diverse customer demands and speed of reaching market are becoming more important alongside with cutting costs.

Lululemon Dogged by Supply Chain Problems

The yoga-gear maker Lululemon has warned that its 2014 first quarter sales will be weaker than expected due to a "meaningful" slowdown in January. Although the retailer was on track to meet its December targets, Lululemon has experienced a steep decline in sales and traffic in the new year. According to Macy's and other retailers, although January is a weak winter for apparel sales, Lululemon has suffered from its unique problems stemming from last year's recall of its popular model of yoga pants, which, due to a production snafu were see-through when users bend over. Compounding the problem was the negative publicity after founder and outgoing Chairman Dennis Wilson seemed to suggest that a new batch of quality problems were in part the fault of overweight customers.

What's more, Lululemon was slow and insensitive on the development of new fashion items. As a result, they ordered the fashion products later than they should have and were suffering from late deliveries. And the mismatch of tops and pants has also caused cancelled orders.

Lululemon's efforts at quality control after last-year recall event have caused more rejected goods so that the supplies for stores are left inadequate. Although they have applied the strategy of fueling demand by purposely keeping product scarce, which helped them maintain premium prices and post outsize sales gains, the short supply has become a major problem now. Adding gas to the fire, Lululemon is also in the midst of management changes which increase the uncertainty of this company.

Lululemon's case shows the supply chain management problems: disruptive quality issues, failure to meet the changing customer demands and fashion, incompatible inventory matches, failure to adjust strategy when situation changes, failure to adjust production plan, uncertain management, unfriendly press exposure... Most of the problems are part of the main challenges that most supply chain professionals are facing now and in the coming future. Lululemon is really a good demonstration of supply chain challenges.

Questions:

When disruptive events happen, is it better to switch marketing/selling strategy immediately or to stick with the old, successful ones which might not be optimal in that circumstance?

Which one is more crucial in apparel industry, fashion or quality? Each industry should focus on its own field and make the right choice.

How to better manage production and inventory matches using advanced supply chain management tools in order to avoiding mismatching problems?

When should the management come to the press and what kind of information should be given to help solve problems not to make them worse? How to utilize an effective PR team?

Reference:

1. http://www.supplymanagement.com/news/2013/the-five-major-issues-facing-supply-chain-leaders

2. http://www.mckinsey.com/insights/operations/the_challenges_ahead_for_supply_chains_mckinsey_global_survey_results

3. http://online.wsj.com/news/articles/SB10001424052702304549504579318120467741330

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.