As we have learned in the previous lecture, the "bullwhip effect" means that the small fluctuation of demands tends to be progressively amplified when moved up the supply chains. Understanding how to tackle the "bullwhip effect" is of significant importance in supply chain management because even a small increase in demand may cause a big snap in the need for parts and materials further down the supply chain.

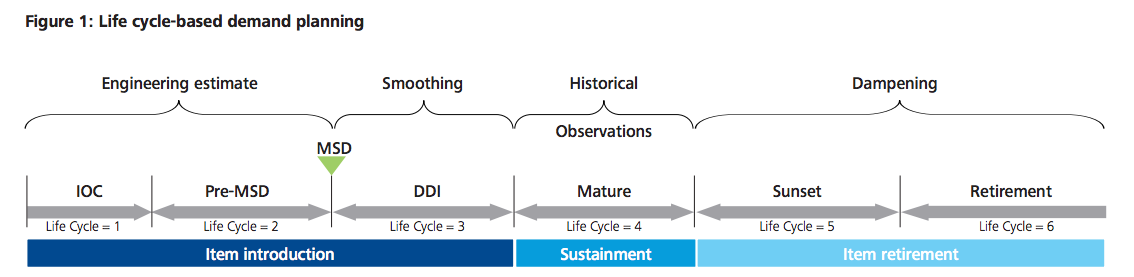

Due to the uncertainty of future demand and the consequential effect on the upstream of the supply chain, companies nowadays put heavy investment on demand sensing and planning. The IDC Manufacturing Insights said that demand sensing and planning applications are currently 8.5% of overall supply chain management spending and are expected to climb to 8.7% by 2015, and the demand planning would stretch across the product lifecycle.

Having known the importance of demand forecasting and planning to mitigate the "bullwhip effect", the next question on table is "how to effectively solve the problem"? Well, one of the most acknowledged ways is sharing information among supply chain members. Sounds easy and fancy? Let's see how P&G and Walmart set a good example after many trial and errors.

The business relationship in 1988 between P&G and Walmart was broken. These two giant market leaders in their own areas were tentative back then in the sense that they never bothered to communicate with each other. In 1985, Sam Walton called Procter and Gamble’s CEO to inform him that Walmart had awarded P&G their prestigious “Vendor of the Year” Award. The sales organization dealt with customers sent Mr. Sam’s call to the corporate office resulted in him being transferred 5-6 times. Having never reached P&G’s CEO, Mr. Walton decided to give the award to another vendor. The CEO of P&G then decided to break the fence and talked to Mr. Walton to see how the two companies could work together to push up sales and improve efficiency. Mr. Walton told him upfront that he thought P&G's internal system was overcomplicated and inflexible. He also hoped that P&G could regard Walmart as an extension/partner of the company. They both agreed to work collaboratively to better manage the demand. The relationship before and after the joint business of these two organizations are vividly illustrated by the image:

The two companies basically built an information highway to connect their respective information systems. For instance, With information shared among the manufacturer and the retailer, the manufacturer can use the information about the inventory level of the retailer to manage the frequency, quantity, and timing of the shipments-- instead of waiting for the retailer to place orders. This practice, referred to as continuous replenishment process (CRP), enables the manufacturer to reduce the inventory necessary and to plan the shipments more efficiently (Clark and Lee, 2000), as was adopted by P&G and Walmart. They also built an Electronic Data Interchange (EDI) to exchange key documents and automatically correct pricing errors. Thanks to the sharing platform, the typical item from P&G currently spends less than 8 hours in a Walmart warehouse. These products shipped to Wal-Mart are the retailer’s shelf within 4 hours, and are usually sold within 24 hours. The companies have successfully grown the joint business from $375 million in 1988 to over $4 billion dollars today!

I personally admire the innovative ways companies use to engage members along the supply chain by leveraging technology. It not only saves trouble for companies, but also delivers greater satisfaction to us customers.

Source: http://scm.ncsu.edu/scm-articles/article/taming-the-bullwhip-effect

http://sloanreview.mit.edu/article/understanding-the-bullwhip-effect-in-supply-chains/

http://www.strategy-business.com/article/11407?gko=7e706

http://www.fortmilltimes.com/2013/09/09/2943822/idc-manufacturing-insights-evaluates.html

http://citebm.business.illinois.edu/it_cases/graen-shaw-pg.pdf

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.