Designing a network for effective distribution

Network designing plays an important role in all type

of industries when delivering, sourcing

and operations are crucial activities. Whether company is planning an

alternative structure, establishing a new plant or going global, it is

imperative to have strategic designing to improve performance at each link of

supply chain. A trade-off is required among

various factors like warehousing cost, inventory carrying cost, transfer freight, delivery freight and service costs to secure competitive advantage.

Challenges:

Dispersed and less harmonized network - hampers optimization of throughput and lead

times to customers

Trouble in simplification of network due to corporate guidelines- troubles smooth material flows

Uneven capacity allocation – cause bottleneck, over

investment in asset and low utilization rate

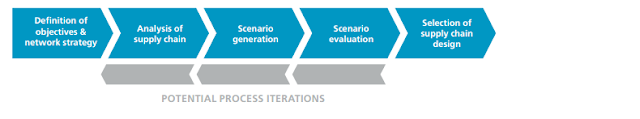

To address the above challenges , a "cradle to grave" approach

is needed to understand geographical and functional scope of company and to

have sustainable operation in long run. A structured sequence planning is

mentioned to enable potential iteration –

(2) Analysis – An in-depth and future focused analysis is needed to understand stakeholders, strengths and weaknesses for refinement

(3) Scenario generation- Alternative business scenario can be created to understand optimal facility location and capacity level

(4) Scenario evaluation – Planning a validation and prioritization process is critical to finalize structure

(5) Selection of design – Business case and implementation plan is essential for final selection

The above analysis can help to design a network strategy but it didn't consider changes in topology, transportation spend and working capital. If the distribution system is centralized then it must have been realized beforehand that holding cost of inventory is more than that of transportation cost. If inventory placement and material flow is not a big concern then it is wise to keep warehouse at economical place and have distributed transportation network. Considering the business drivers and performed simulation test, it is possible to understand complexity and inventory optimization. Accordingly, holistic design and change management activities are required to have an agile, adaptable and aligned supply chain logistics network.

Source: Supply Chain Management Logistics & Distribution

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.