Lean manufacturing

strategies have been successfully implemented in a wide variety of Industries

other than manufacturing industries.

Amazing examples are from Food chain restaurants such as Subway to

product development in IT Industry.

Lean software overview : http://www.youtube.com/watch?v=P3A9JPb3KqQ

The

seven principles of lean manufacturing can be applied to optimize the whole IT

value stream. These principles are:

1. Eliminate waste. What’s

a waste? Any activity that does not directly add value to the finished product.

Sources of waste in

software development are the addition of

Unrequired features (

fancy features which is called Gold Plating : http://en.wikipedia.org/wiki/Gold_plating_(software_engineering)

Project churn and

Crossing

organizational boundaries (different teams)

Development teams should

be able to self-organize, change plans, quit working for a feature which is

identified as not required.

Reduction of scrap and

rework late in the lifecycle is also required to reduce Project churn.

2. Build in total quality: To build quality software the testing has to

be done for every features and module based. Testing along with development is

the best option if we do not want to see huge number of defects during the

first release. A testing team, aligned with development team can do the job in

a better way. The policy is to build a feature, test it, fix any issues with it

and iterate this for every feature. It is also

called test driven development.

3. Create knowledge. Knowledge management

is critical for a products success. This can be referred to the cross-functional

knowledge between teams and knowledge about what customer or stakeholders want

or what kind of problems we are going to solve. This knowledge gives deeper

visualization and helps to build revolutionary products.

4. Deferring

commitment: It’s probably better to start

development without a complete specification on features and time because we

know scope creep happens. The teams, architecture should be fliexible enough to

adopt any changes.

5. Deliver quickly. Work load

for teams should be limited based on team’s capacity. In Agile based

development the team chooses which functionality to build. Here the time is

fixed. In agile method teams don’t try to do more than they are capable of, but

instead they self-organize and determine what they can build. This way the

teams can actually show valuable deliverables and in less time shippable

product can be made.

6. Engaged people: More productivity

with a higher quality can be achieved only by an engaged work force who think

critically. Higher motivation, less

control over the team can create an engaged work force which is again an idea

comes from agile.

7. Total Optimization: Scrum master or product manager should be

able to view the whole picture supporting the vision. A highly sustainable and high

quality product can be made by managing programs, team, multiple

projects, business processes and interrelated systems, and this way the IT

value stream can be improved.

Here is a video how Toyota Lean strategies are incorporated in Lean software development

http://www.youtube.com/watch?v=I5gN66KFtaI

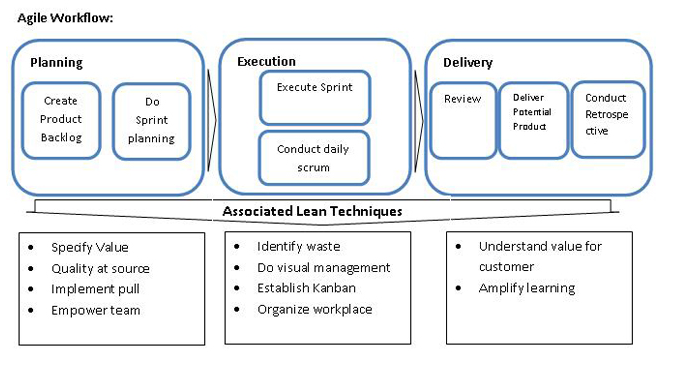

Lean process goes well

with agile development though there are multiple similarities and dissimilarities:

The differences are

very technical. Therefore I am proving a link for the people who want to know

the technical differences between agile and lean-

Lean is important for scaling agile in several ways:

1. Lean is probably an

explanation why agile works

2. It provides

techniques for identifying waste

which makes agile more flexible and effective

3. Lean offers insight

into strategies for improving the software process

- Value stream mapping ( Find more http://www.youtube.com/watch?v=HKxL_S47yJg)

Can you think of specific types of software products where only Agile or only Lean have more chances of success?

Sources:

Great presentation this very necessary for us to be have the knowledge all about this, really appreciable blog!

ReplyDeleteKaizen Training